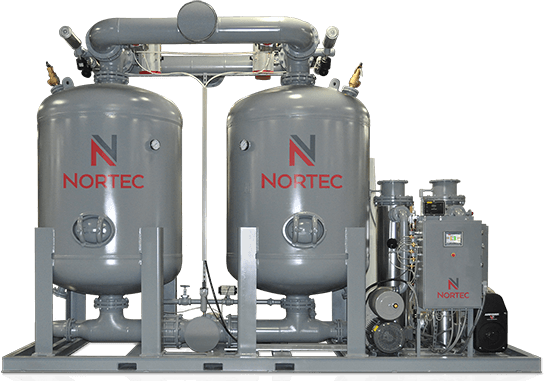

Internally Heated Desiccant Dryers

Custom Design To Fit Your Application

Internally Heated Desiccant Dryers PDF

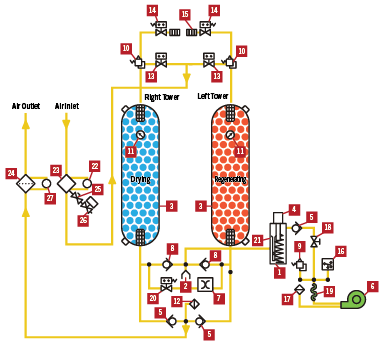

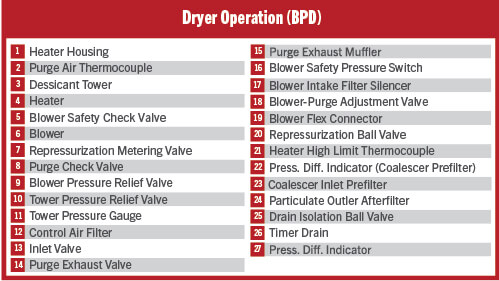

Nortec Internally Heated Regenerative dryers supply super dry, -40º F/C pressure dew point air for critical requirements for pneumatic instruments, controls and sensitive process air. Our Internally Heated Desiccant systems are custom built to customer specifications and requirements.

Advantages:

- Adjustable individual thermostats and purge flow rates, for energy-saving

- Intelligent valve control for the most reliable tower cycling.

- Desiccant Protection

- Long Valve Life

- Energy-Efficient Regeneration

Industry-Standard Performance

And Exceptional Quality

Optional Features

- NEMA 4 control enclosure

- Color change moisture indicator

- Mounted filters and bypass piping

- Audible alarm

- Full flow safety relief valves

- Digital dew point readout

- Dew point demand switching

- Energy saver

- Failure to switch/purge/pressurize

- High dew point indicator

Standard Features

- On/off switch

- Power on light

- Heater on light

- Activated alumina desiccant

- Desiccant fill/drain ports

- Stainless steel desiccant screens

- Rigid copper pilot air lines

- Control air filter

- 460V/3PH/60HZ supply power

- 115V control voltage transformer

- Permanently lubricated inlet transfer valve w/position indicator and depressurization safety

- Purge flow control valve w/pressure gauge for flow indication

- Purge exhaust mufflers

- Mechanical timer

- NEMA 1 control enclosure

- Main power and control power fuses

- Main power and control power fuses

- Heater contactors

- Heater safety guards

- Adjustable heater thermostats

- -40 Deg.F/C pressure dew point

- Interlock Logic valve control

- Tower mounted tower pressure and temperature gauges

- Controlled repressurization

- Controlled repressurization

- ASME code pressure vessels

- Enamel exterior finish

- Tower lifting lugs