Industrial Water Savers

Low Capital Investment. Long Life and Low Maintenance.

Our Water Saver Closed Loop Cooling System significantly reduces energy costs by removing heat from water cooled machinery. The process reduces temperatures to slightly above ambient, eliminates corrosion and contamination, and eliminates need for an outside water supply and sewer.

This can produce significant increases in production efficiency and significantly lower your costs by cutting water usage. The closed-loop system eliminates the possibility of corrosion and contamination, and our system can be custom designed to your application for quick and easy installation and commissioning. It requires little or no maintenance.

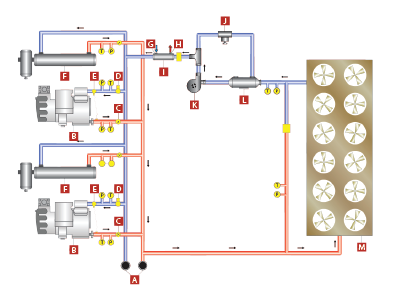

Typical process cooling fluid (water with varying proportions of glycol) is circulated through the closed loop system by using pumps. Ambient air is sucked from the bottom of the Water Saver. This results in a steady flow of air around the tubes carrying the cooling fluid. With the use of thermally activated valve (optional) and an additional trim-cooler, temperatures very close to ambient and below can be achieved

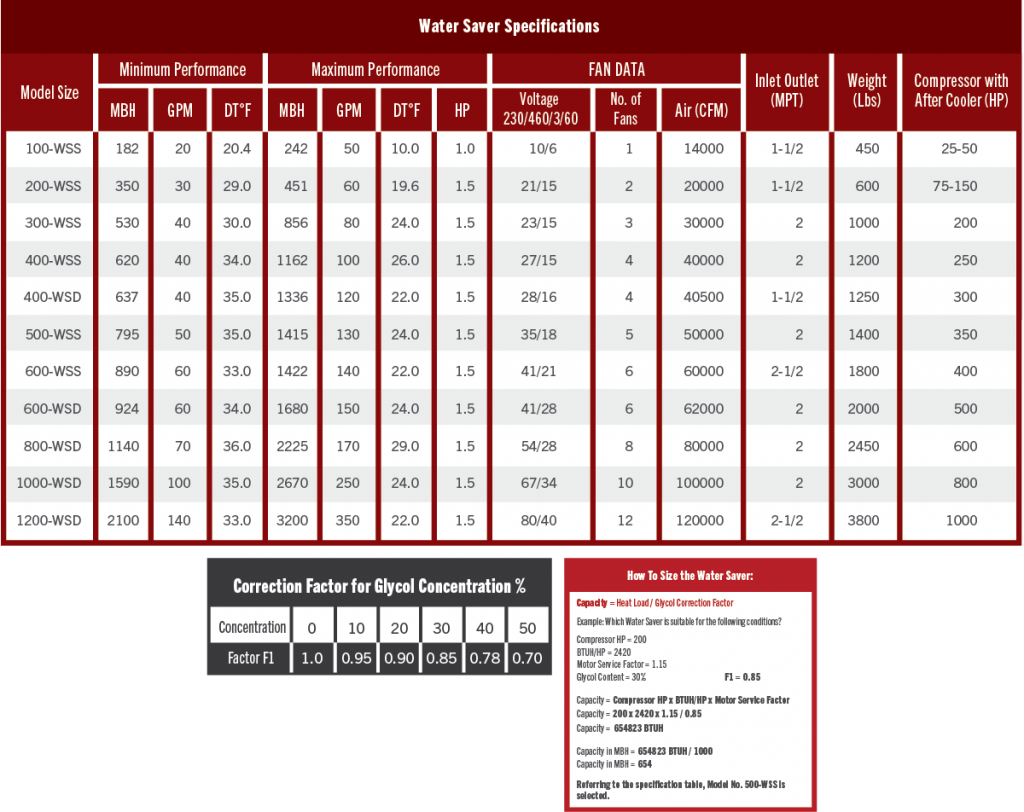

| Model No. | Min. MBH | Min. GPM | Min. DT0 F | Max. MBH | Max. GPM | Max. DT0 F | HP | VOLTAGE 230/460/3/60 | NO: OF FANS | AIR (CFM) | INLET OUTLET (MPT) | WEIGHT (LBS) | Compressor with After Cooler (HP) |

|---|