Closed Loop Fluid Cooler And Pumping Station

Efficient. Lower Energy Costs.

Our Water Saver Closed Loop Cooling System significantly reduces energy costs by removing heat from water cooled machinery. The process reduces temperatures to slightly above ambient, eliminates corrosion and contamination, and eliminates need for an outside water supply and sewer.

This can produce significant increases in production efficiency and significantly lower your costs by cutting water usage. The closed-loop system eliminates the possibility of corrosion and contamination, and our system can be custom designed to your application for quick and easy installation and commissioning. It requires little or no maintenance.

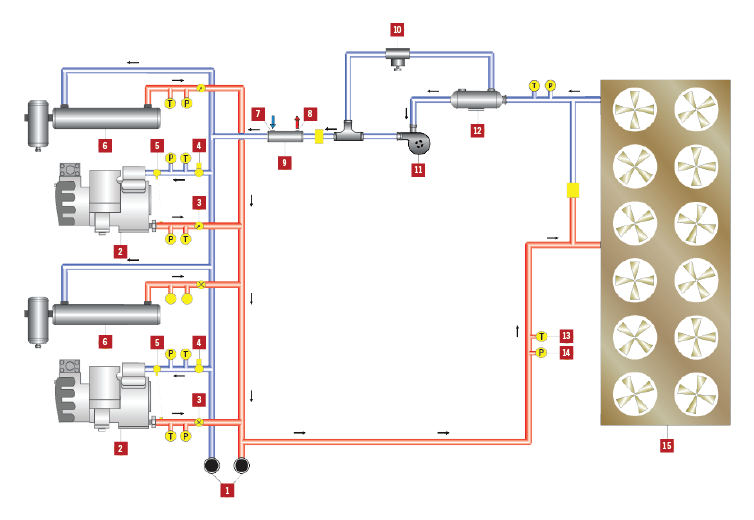

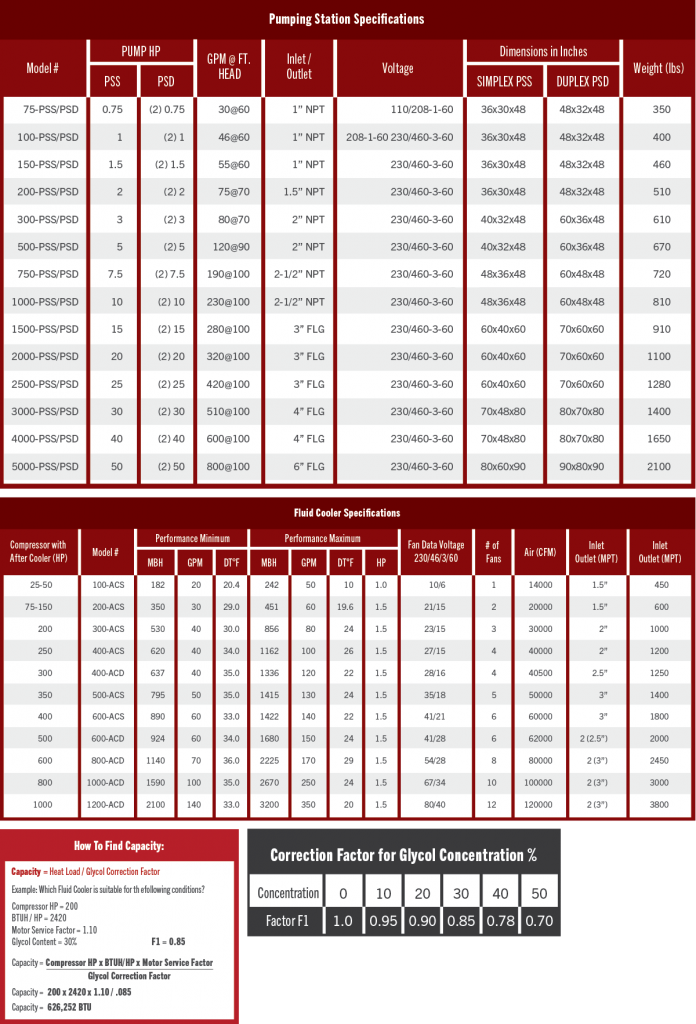

Typical process cooling fluid (water with varying proportions of glycol) is circulated through the closed loop system by using pumps. Ambient air is sucked from the bottom of the Water Saver. This results in a steady flow of air around the tubes carrying the cooling fluid. With the use of thermally activated valve (optional) and an additional trim-cooler, temperatures very close to ambient and below can be achieved.

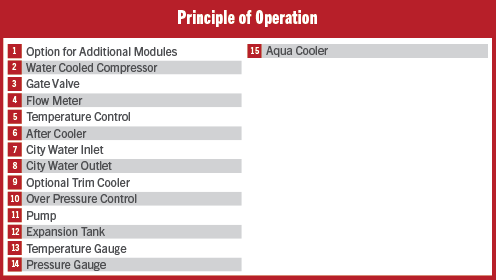

Nortec provides the choice of either a Single (PSS Series) or a Double (PSD series) pumping station. The typical pumping station package includes the pump, the starter, your choice of NEMA enclosure along with monitoring lights and On/Off switch. The entire unit is pre-piped and mounted on a skid. The PSD series comes with 2 pumps and separate control valves. These units come with standard of 230/460 voltage. Optional voltages are also available upon request.

Industry-Standard Performance

And Exceptional Quality

Optional Features

- Specially coated fins (copper, polyester, phenolic-coated coils)

- TEFC fan motors

- Easy access coil cleaning panels

- Fan cycling control system

- NEMA 4 controls

- Corrosion resistant – heavy gauge embossed aluminum.

- Special copper coils

- Bypass fluid control valves

- Temperature controlled fan speed

Standard Features

- Vertical/horizontal air discharge configuration galvanized steel frame and casing

- Durable aluminum casing

- Aluminum fins mechanically expanded into copper tubes

- 6 pole, 230/460V, Single/Three Phase, ODP Fan Motors

- Fully baffled fan sections

- NEMA 3R suitable for outdoor installation fan motor starter

- Fan motor fusing

- Close coupled centrifugal pump (optional) pre-piped, factory assembled and tested

- Standard design for vertical airflow. (Horizontal airflow is available as an option).

- All units are UL & CUL and MEA – listed.

- All units are constructed of heavy-gauge, corrosion resistant galvanized steel for maximum casing rigidity. Multiple fan units are separated by full width baffles to prevent air bypass.

- This provides additional casing reinforcement.

- To enhance the tube life, all end panels, center supports, and partitions have collared tube holes.

- The fluid coils are constructed using seamless copper tubing on a staggered pattern. Tubes are mechanically expanded into continuous full-collared plate-type aluminum (or optional copper) fins for permanent metal-to-metal contact.

- Headers come equipped with vents and drains.

- All coils are factory pressure and leak tested at 400 PSI.

- Aluminum fans with painted steel hubs are dynamically balanced and factory tested before shipping to ensure quiet operation.

- Fan guards are designed from heavy-gauge, close-meshed steel wire with vinyl coating for maximum rigidity, long life and attractive appearance.

- Fan motors are heavy duty PSC or three phase open drip-proof type with permanently lubricated ball bearings and built-in overload protection. All motors are factory wired with leads terminating in a weather-tight enclosure located opposite the header end of the unit.

| Model No. | Pumping Station Single | Pumping Station Double | GPM@ft. Head | Inlet/ Outlet | Voltage | Dimensions (single) (inches) | Dimensions (duplex) (inches) | WEIGHT (lbs) |

|---|

Nortec Water Saver System Advantages

Pumping Station-Single (PSS)

Nortec closed-coupled and base-mounted centrifugal pumps provide economical performance for a wide range of applications of varying flow rate and head pressure. (Flow rates up to 500 GPM and head pressure up to 140 feet).

Pumping Station-Double (PSD)

The double pump setup is mounted on a heavy skid with a separate regulating valve for each pump. The pump setup come with an isolation valve and maintenance activities can be carried out without shutting down the system.

NEMA Electrical Controls

Nortec Pumping stations are equipped with your choice of NEMA enclosures. Optional control and monitoring indicators can be added along with state-of-the-art controllers.

System Controllers

Optional state-of-the-art controllers are used for optimizing the performance of the pumping stations. The PLC’s (Programmable Logic Controllers) are designed with ease-of-use in mind. Their modular and versatile features make it suitable for your applications – including local and remote display. Optional PC connections are also available.

High Efficiency Trim Coolers

The trim coolers are mounted in-line with counter flow and are typically shell and tube or plate type. They monitor the outlet temperature and with an optional auto-regulating feature and ensure consistent inlet temperature to the heat source. Additionally, they have bleed and drain valves for maintenance purposes.

Three-Way Thermostatic Valve

These modulating thermal valves are designed to bypass around coolers during start-up and then provide accurate temperature control for cooling systems during normal operation. They do not require any outside control to operate.

Autodual Controller

The universal pump controller incorporates the latest in electronic technology in a compact and user-friendly enclosure. The controller is independent of the pump size. The fail-size design ensures that the pumping station will operate at the maximum level of efficiency. With its monitoring capability, it enables equal running time of the pumps. This makes it convenient to schedule maintenance activities.